2-stage belt drive and additional electronic control enables spindle speeds up to 5,000rpm. The right cutting speed for even the smallest pieces. For face turning, longitudinal turning, boring, taper turning, slicing and drilling. Complete with 3-jaw chuck and live centre. Centre distance 150mm. Swing 55mm. Height over cross slide 33mm.

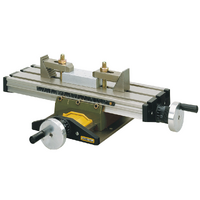

Machine bed with dovetail guides of continuous casting aluminium.

Die-cast aluminium spindle headstock. With quiet special DC motor, 2-stage belt drive and additional electronic speed control for high engine power at low speeds for larger work pieces and for the appropriate cutting speed, even for the smallest pieces. Main switch with emergency stop function and restart protection. Precision bearing mounted main spindle with continuous 8.5mm bore. Chuck fit for standard ER 11 type collets.

Three-jaw chuck, self-centering. Inside jaws 1.5 - 32mm, outside jaws 20 - 50mm.

Die-cast aluminium tailstock with spindle and live centre (fitting MK 0/ short).

Support: To be shifted manually on the bed and clamped with lever. Rotating tool post for turning steels 6 x 6mm. Processing via top slide (60mm, travel distance Z) and cross slide (40mm, travel distance X). The angle adjustment of the upper carriage makes it possible to turn tapers up to +/- 45°.

Handwheels with zero adjustable scale ring (1 division = 0.05mm, 1 revolution = 1mm).

Other technical data:

230V. 50/60Hz. Distance between centres 150mm. Swing 55mm. Height over cross slide 33mm. Cross slide travel (X) 40mm, top slide travel (Z) 60mm. Steel tool post for turning steels 6 x 6mm. Spindle bore 8.5mm. 2-stage belt drive with electronic speed control: Stage 1 = 800 - 2,800rpm. Stage 2 = 1,500 - 5,000rpm. Dimensions approx. 360 x 150 x 150mm. Weight 4.5kg. Insulated to class 1.

-

vernier caliper in photo is NOT included

-

centre distance: 150mm

-

swing: 55mm diameter

-

height over cross slide: 33mm

-

cross-slide travel: 40mm

-

top slide travel: 60mm

-

steel tool-holder: accepts 6mm x 6mm cutters

-

spindle bore: 8.5mm

-

spindle speeds with continuous variation: 500-2500 rev/min, 1000-5000 rev/min

-

tail-stock spindle: MT1 bore (short)

-

tail-stock travel: 30mm

-

internal chucking capacity: 1.5mm - 32mm

-

external chucking capacity: 20mm - 60mm

-

hand-wheel resolution: 1 revolution = 1mm feed (20 divisions)

-

mass: 5.1kg

-

dimensions: 450mm x 230mm x 205mm

These extra accessories are available separately:

ROEHM drill chuck for FD 150/E (0.5 - 6.5mm)

6-piece HSS lathe tool set for FD 150/E

Multiple Range Collet Set for FD 150/E

Product Video available below:

https://www.proxxon.com/en/video/24150.mp4

Product Manual (including spare parts list) available below:

(24150)

| SKU | 24150 |

| Brand | Proxxon |

| Shipping Weight | 6.1000kg |

| Shipping Width | 0.450m |

| Shipping Height | 0.250m |

| Shipping Length | 0.250m |

| Shipping Cubic | 0.028125000m3 |